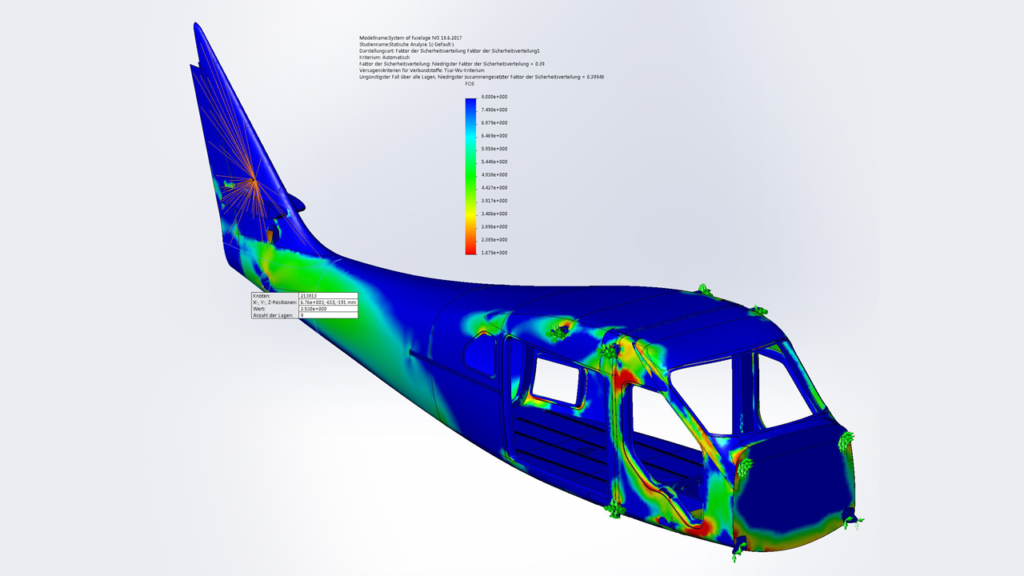

Composites and FEM Analysis

In recent years, we have been able to gain a great deal of experience in the production of particularly lightweight fibre composite structures. Often the excellent properties of these materials are not exploited by far. Many structures are not designed to be fibre composite and the coating thickness is often too thick and not optimally used.

A simple, lightweight and comparatively inexpensive solution is always our priority.

Composites

Within the last eight years the Silence Aircraft GmbH has been able to collect a lot of experience with composite materials

The design of light structures is the key for dynamic, efficiany and easy handling.

Industrie composite

The variety of applications for which composite is suitable is extremely impressive. Thanks to its numerous benefits, in particular its high stability despite the low weight, new fields in which fibre composites made of carbon and glasfiber can be used appear every day!

Thanks to state-of-the-art technology, nothing stands in the way of even extraordinary ideas.

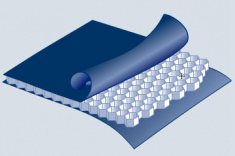

Vaccum baging and RTM

Technology for the production of components with complex geometry like honeycomb sandwich structures.

Pressforming

Technology for the production of structural components with straightforward geometry.

Joining/bonding technology

Core competence of Silence Aircraft, indispensable when integrating complex assembly units.